A laminar flow hood is a vital device in the control of particle contamination. Laminar airflow is defined as air moving at the same speed and in the same direction, with no or minimal cross-over of air streams (or “lamina”). By contrast, turbulent flow creates swirls and eddies that deposit particles on surfaces randomly and unpredictably. Most contamination-sensitive environments such as dust-free hoods require laminar flow because it predictably sweeps particles in a uniform direction, from the cleanest area under the hood (the filter face) to the exit area, which is generally the sash opening or vents along the back or bottom of the hood. The design ensures that the cleanest (and most germ-free) area will always be the upstream area closest to the filter face. This non-contaminating configuration applies to both horizontal and laminar flow hoods and is commonly used in the case of compounding sterile products, particularly in compliance with USP 797 and USP 800 standards. Work is generally done in the clean zone, as far as possible from obstructions that create turbulence.

But which direction is better: vertical airflow (downward from a filter positioned above the work surface) or horizontal airflow (forward from a filter positioned behind the work surface)? There are compelling reasons to choose either airflow system, depending on clearance requirements, process location, work surface design, and operator safety.

Laminar Airflow Definitions

Laminar airflow hood terminology differs based on several attributes, which may reflect proprietary technology references, included/excluded system components, the type of hood enclosure, and the type of air handling methods.

A Laminar Flood Hood is a specific reference to a contained enclosure that produces laminar flow air via an integrated blower and HEPA filter. Meanwhile, a laminar flow hood workstation typically refers to a combined system that includes the flow hood, as well as an integrated worksurface or table that supports the flow hood enclosure.

Definition: Laminar Airflow

Laminar Flow refers to a fluid motion characterized by smooth and orderly movement without any significant turbulence or disruptions. It typically occurs when a fluid, such as a gas or liquid, flows in parallel layers with minimal intermixing between them. In this type of flow, particles within the fluid follow a predictable path and exhibit uniform velocities.

Definition: Turbulent Airflow

Turbulent Airflow refers to the irregular and chaotic movement of air or any fluid medium. Unlike laminar flow, turbulent airflow is characterized by unpredictable fluctuations and mixing of fluid particles. It involves swirling vortices and rapid changes in velocity and pressure, creating a less structured and more disorderly pattern of flow.

Vertical vs Horizontal Laminar Airflow Hoods

Definition: Horizontal Laminar Airflow Hood

Horizontal Airflow Hoods refer to an enclosed workstation or equipment that produces horizontal laminar airflow from back to front within a confined area. These configurations require less overhead clearance than a vertical flow hood because the blower and filter panels are located on the back side of the enclosure instead of the top side.

Horizontal Laminar Airflow denotes the controlled and uniform movement of air in a horizontal direction. For laminar airflow hoods, airflow typically flows from the back of the cabinet to the front of the cabinet. Horizontal flow cleanrooms have the same working principle as a horizontal flow hood and produce wall-to-wall airflow that flows in parallel to the floor.

Definition: Vertical Laminar Airflow Hood

Vertical Airflow Hoods comprise a HEPA blower hood with enclosed side panels to generate top-to-bottom ISO 5 laminar flow air. Downward airflow sweeps particulate downward and out through the opening in the front sache. Vertical airflow hoods are common for sterile and aseptic workflows in microbiology, pharmacy compounding, cell culture, proteomics, and mycology where successful outcomes require sterile protocols.

Vertical Laminar Airflow (VLF) refers to the controlled and uniform movement of air in a vertically oriented direction. In this configuration, the air flows from the top to the bottom or vice versa in a laminar manner, maintaining a consistent downward or upward path. Vertical laminar airflow is commonly employed in environments that demand particle-free or sterile conditions to prevent contamination or maintain specific temperature and humidity levels.

The backbone of Terra’s Vertical Laminar Flow Hood (VLF) is a fan filter unit (FFU) that incorporates a 3-speed, direct-drive 1/3-horsepower electric motor that forces air through a HEPA filter. In conjunction with the system’s pre-filters, the HEPA filter removes 99.99% of all particles 0.3 microns and larger from the air stream. At the default speed, each 2’ x 4’ FFU provides 750 CFM (cubic feet per minute) of filtered air at 90 FPM (feet per minute), which test results show exceeds ISO 14644-1 for an ISO 5 environment.

Terra's VLF Stations feature Room-Side Replaceable (RSR) FFUs, which allow the HEPA filter to be easily replaced without disassembling the blower unit (see Section 5.2 Filter Replacement).

Read More: How Do Room-Side-Replaceable FFUs Save Time and Money?

Definition: BioSafe® Universal Laminar Flow Hoods

Terra's Universal Laminar Flow Hoods allow you to create a laminar flow hood from any existing table or workstation. This type of system only includes the enclosure and HEPA blower system so that it can be outfitted with any type of table or workstation that the user requires for the application.

BioSafe® Universal Hoods offer the ultimate HEPA enclosure for optics, microelectronics, genomics, proteomics, and cell biology. The turnkey system includes a hood frame, adjustable speed blower, LED lighting, status indicator, and cleanroom-grade, UL-listed HEPA-filtered air (99.97% efficient at 0.3µm particle diameter). BioSafe® design eliminates cracks and crevices for easy cleaning and sterilization. The 304 stainless steel frame supports easy disinfection, wipedown, and sterilization for medical devices, USP compounding, and biotechnology use. This design meets or exceeds virtually any industry cleanliness standards including ISO 5 / Class 100 for CGMP, IEST, ASTM and ISO 14644-1. Select the optional ULPA filter for ISO 4/Class 10.

Laminar Airflow Diagrams

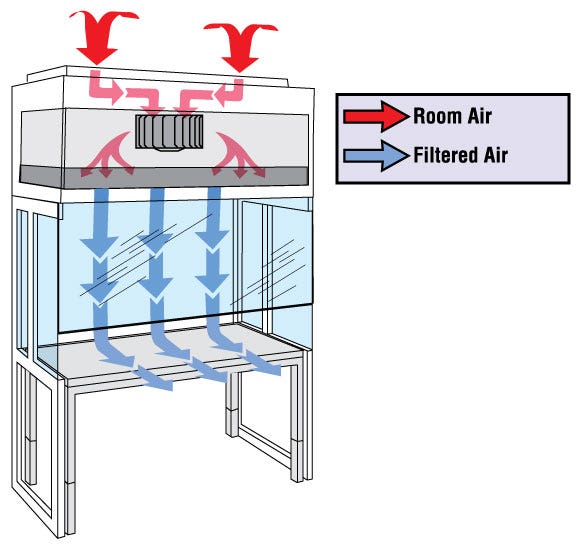

Vertical Laminar Airflow Diagram

Room air (in red) enters the system from above the HEPA filter; 99.99% particle-free air is forced downward toward the work surface.

A clean bench using a vertical laminar flow design is also preferable where floor space is at a premium. Because this configuration stacks the fan/filter module on top of the hood, a vertical laminar flow hood can generally be installed on a standard lab bench.

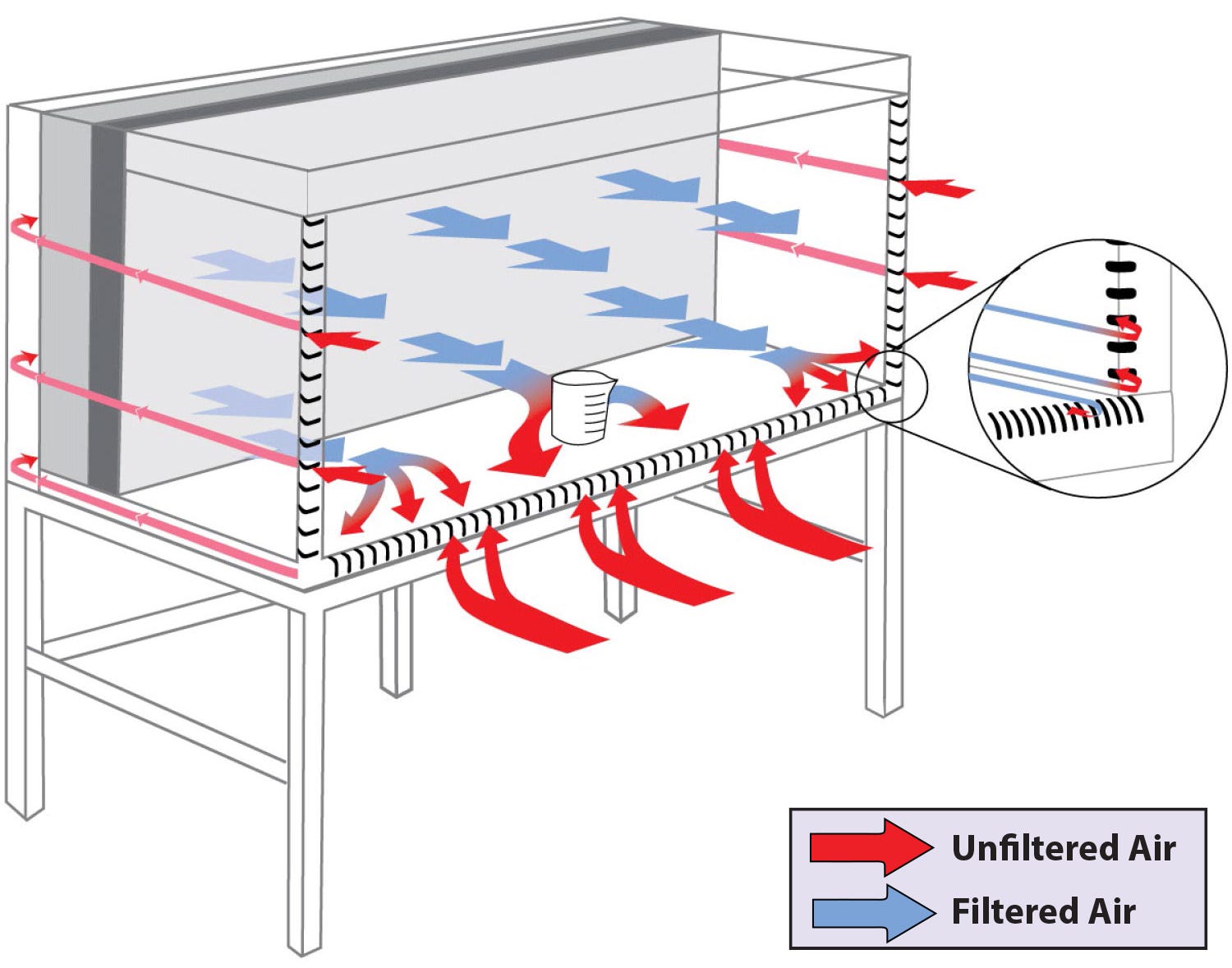

Horizontal Laminar Airflow Diagram

Horizontal laminar flow hood designs provide airflow that is parallel to the work surface for less turbulence. Horizontal flow hoods also allow for sterile materials laying on the work surface to be positioned closer to the filter face (upstream from other potential contaminants).

Vertical Laminar Flow Hood Advantages

- The Hood is not as deep: requires less floor space

- Safety: air not blowing directly at operator, and sash provides a barrier in front of operator’s face

- Filter on top: easier to access

- Less turbulent effect from air striking large objects or processing equipment

- Less cross-contamination of items positioned on the work surface

- More working height for tall or large equipment

Vertical Laminar Flow Hood Disadvantages

- Overhead clearance requirement; changing filters or servicing unit may require a step-ladder

- Cannot place items or hands on top of other items: obstructs airflow

- Increased turbulent effect of air striking work surface

A horizontal-flow hood requires additional depth to accommodate the rear-mount filter/fan unit with some additional rear clearance to allow air to enter the system. These clearance requirements necessitate a deeper bench and more floor space than a vertical flow system.

Although both airflow designs provide effective sweeping action near the filter face, their respective flow patterns eventually encounter disruptions that often tip the scale in favor of one or the other configuration. In a vertical-flow hood, the obvious obstacle is the work surface. A perforated or rod-top work surface allows the laminar air stream to pass through the hood with minimal obstruction, but these tops can be a problem in operations involving liquids or small parts. If you’re working with these materials and want to avoid picking up parts off the floor, a horizontal flow design may be preferable.

Yet even a solid top may not rule out vertical flow if work is performed above, not on, the work surface. If sterile or particle-sensitive processes are performed in a clean, sterile zone midway between the work surface and the filter face, a vertical flow hood is generally acceptable. As long as hands and other contamination sources move up and down, not sideways above a sample, sensitive materials will remain clean.

Read More: The Importance of Airflow Uniformity - Terra Universal Blog

Finally, consider the effects on operators of air exiting the laminar flow hood. Although horizontal laminar flow, with air traveling from the rear of the hood and exiting the front opening, may not encounter large obstructions inside the hood, it does eventually encounter the person performing the work. Any annoying substances, such as soldering fumes or fine powders, may be blown into the operator’s face. While this collision may not compromise the laminar flow where work is performed, it may pose a health risk. In such cases, vertical flow is probably preferable.

Horizontal Laminar Flow Hood Advantages

- Laminar airflow is parallel to work surface, eliminating turbulent effects from vertical airflow striking perpendicular to work surface

- Easier to position and stagger sterile equipment and materials on work surface closer to the filter face (upstream from other potential contaminants)

- Hands and gloves are generally less contaminating since they’re downstream of the sample

Horizontal Laminar Flow Hood Disadvantages

- Filter change or service usually requires repositioning hood for rear access

- Large samples obstruct laminar air flow, may contaminate downstream samples

- If used without sash, can blow fumes and/or powders into operator’s face

Other Considerations

Some final considerations involving both vertical and horizontal laminar hoods:

1) Neither vertical nor horizontal laminar flow hoods are appropriate in the presence of biohazards. Only an approved containment system, such as a Class II, Type A2 Biosafety Cabinet, should be used in applications requiring Biosafety Level (BSL) 2 or 3 containment.

2) Whichever laminar flow hood design you choose, be sure to run it for at least 15 minutes before you begin critical operation, to allow particles to be purged from the enclosure.

3) Remember the sweeping direction, from clean to dirty, whenever you clean a hood. Wipe down surfaces in smooth, linear motions beginning at the filter face and moving downstream, with the air flow. Likewise, perform “dirty” operations, like unpackaging samples, as far from the filter as possible.

Related Posts: How to Clean a Laminar Flow Hood

Still not sure what style of Laminar Flow hood you need? Chat with our representatives now!

More Information About Horizontal & Vertical Laminar Flow Hoods